Die Sink Edm

Die-sink EDM was a developed methodology discovered by BR Lazarenko and N. Die sink EDM occurs when both the electrode tooling workpiece is submerged in light oil acting as an insulator where the constantly running dielectric fluid allows the temperature of the workpiece to be maintained.

These abilities combined with a high demand for complex parts from the automotive aerospace and medical sectors are making EDM.

Die sink edm. Machines a wide range of materials. All the knowledge of our experts to offer you a compact economical and quality machine. They are Pressure Flushing Suction Flushing and Side Flushing.

Die-sinker EDMs work by using an electrical discharge to erode workpiece material. Developments in the EDM process and its technology along with improvements in accuracy automation and micro-moldmaking technology can pay enormous dividends to the domestic moldmaking industry. The technique has similarities with die-sink EDM but in this case the electrode is a rotating tube conveying a pressurized jet of dielectric fluid.

Die-sinking EDM machines manufactured to maximize reliability. 400 a 1000 mm 157 a 3937 in. EDM Wire and Die Sink The demands for ever increasingly delicate and complex components and higher aspect ratios have sometimes limited the designers freedom to create components.

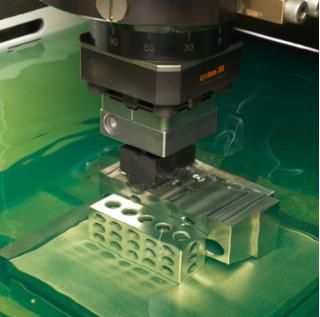

It is used to impart multifarious blind shapes and surface curvatures. The sinker EDM process is commonly used in the production of dies and molds. The sinker EDM machining Electrical Discharge Machining process uses an electrically charged electrode that is configured to a specific geometry to burn the geometry of the electrode into a metal component.

EDM PERFORMANCE MEASURES A significant number of papers have been. The shapes and tolerances produced by this method are next to impossible to create using traditional machining techniques. Increasing drive speed is one solution to improving the speed of die sinking EDM.

Electrical discharge machining EDM is a unique process. It has everything you need This multifaceted die-sinking electrical discharge machining EDM performer delivers best value for the investment in the production of molds and parts. This led them to invent an EDM machine used for working difficult-to.

There are many methods of flushing. We are presenting one of the major success stories of our company the big size EDM die sinker line Gantry Eagle 1400 and 1400 PlusThis portal type EDM mach. Die sinking EDM also called conventional EDM employed a tool electrode having a profile matching with the intended shape.

Lazarenko who were investigating ways to prevent the erosion of material contacts due to sparking. The AL40G and AL60G incorporating the latest electrical discharge control technology together with Artificial Intelligence functions and a precision thermal compensation system as well as Sodicks own market-leading linear motor technology. 300 a 750 mm 118 o 2952 in.

When electrical voltage is applied and becomes high enough a breakdown of the dielectric occurs. Speed Is Not the Solution. Die-sinking EDM uses an electrode typically a specific grade of carbongraphite that sometimes is impregnated with copper to burn complex shapes into a variety of metals to create certain detail on the mold itself.

Ajay Baban Palve1 Mr. The dielectric fluid also causes vaporized hard material to be flushed out. 300 a 650 mm 118 o 2559 in.

Two Russian scientists B. The electrical current circulates through the ionized channel and the discharge is created. Sodick Europe is delighted to announce a new generation of high-precision EDM die sink machines.

And has automated dielectric management extended. EDM drilling or fast hole drilling was designed for producing fast accurate small and deep holes. Die-Sink EDM Forms Complex Parts.

Eroded particles should be flushed out at the earliest. Of Production Engineering 3HOD Dept. These two russian scientists discovered that the erosion was more controlled.

In the current paper we present the research focused on analysing the capability for implementation of die-sink EDM in meso - micro scale. The machine uses an electrode to conduct thousands of tiny sparks to the workpiece in turn burning the detailed shape. Starting with the most favorable floor space to work surface area ratio this sinker EDM solution offers superb accessibility.

Flushing System and Pressure The dielectric fluid must be circulated freely between Tool and Work Material. A review on die sink EDM process Mr. The electrode usually has a larger face.

Micro EDM has been identified since more than a decade as suitable process for machining complex shaped structures with high aspect ratio though only through variations of EDM such as micro EDM milling micro EDM drilling coated electrodes etc. Bringing both the copper electrode a conductive material metal workpiece within a small range apart. How Sinker EDM works.

It can make a hole 25 cm deep in about a minute and is a good way to. In this way the unproductive times for lifting movements are reduced. They failed in this task but found that the erosion was more precisely controlled if the electrodes were immersed in a dielectric fluid.

Lazarenko were tasked in 1943 to investigate ways of preventing the erosion of tungsten electrical contacts due to sparking.

Pin On Erowa System 3r Workholding System

Perfect Contour Cuttings Thanks To The Awo And Wbc Functions In Order To Make A High Performance Punching And Stamping Tool Function Stamping Tools Edm Modern

Die Sinking Edm Edm Sink Conductive Materials

A New Mold Cavity Work Under Sinker Edm Ordered By German Customer Diesinking Edmdiesinking Sinkeredmmachining Plunge Injection Moulding Molding Machinist

Agiecharmilles Form P 350 600 900 Die Sinking Machines Edm Edm Ceiling Lights Machine

Pin On Sodick Imts 2014 Exhibit

Gf Machining Solutions Tooling In Die Sinking Edm Covers All Needs Of Palletized Electrodes And Workpieces Palletized Means Machining Process Edm Automation

Pin On Edm Tooling Fixture Workholding Chuck Vise

Die Sinking Edm Of Special Punches With Cross Made Of High Wear Resist Tool Steel And Will Be Coated Later Www Taiyouprecision Com Pun Tool Steel Steel Edm

Pin On Edm Wire Cut High Speed Machining Cut 200 Sp

Pin On Erowa System 3r Workholding System

Die Sinking Edm Noviform Universal Noviform 600u Source Http Www Novickedm Com Products Categ1 Die 20sinking Computer Numerical Control Locker Storage Edm

Die Sinking Edm For Slide Insert Of A 4 Cavity Mold Material Assab 8407 Taiyou Is Looking For Sub Contract Service For Mold And Die Ins Molding Cavities Edm

Posting Komentar untuk "Die Sink Edm"